Flat 50% Off on First Order

Buy 1 Get 1 Free on Select Items

Free Shipping on Orders Above ₹999

Flat 50% Off on First Order

Buy 1 Get 1 Free on Select Items

Free Shipping on Orders Above ₹999

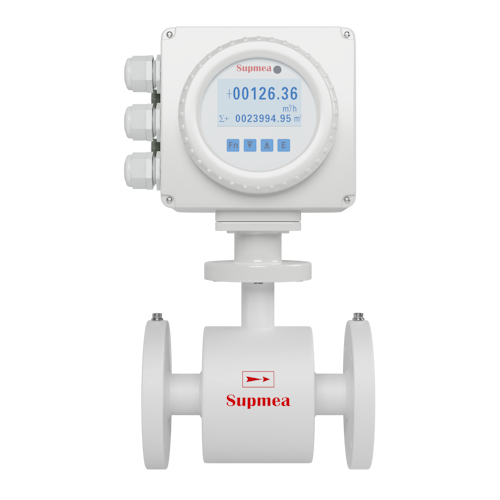

Supmea's electromagnetic flow meter does not contain any moving parts, rotating gears or turbines, or bearings. Instead, it relies on two electrodes to measure the density of the induced magnetic field that results from an electrically conductive fluid, such as water, flowing through a pipe. So there is no susceptibility to bearing wear or other mechanical wear-and-tear issues. As for the electrodes and the liner used in electromagnetic flow meter, these components can be fabricated from a variety of materials to make the mag meter compatible with virtually various electrically conductive fluid, including aggressive acids. The only limitation of the electromagnetic flow meter is that the measured fluid media must be electrically conductive (>5?S/cm). Non-conductive fluids, such as oil and other petroleum-based fluids, cannot be measured with mag meter technology.

Features

Applications